Modern technologies make it possible to thoroughly control the process of oil products transportation, guaranteeing safety and transparency of logistics. One of the advanced solutions in this area is the fuel tanker monitoring system created by Mechatronics . It includes sensors of fuel level, tilt angle, pressure and liquid presence connected via RS485 network. To ensure explosion protection, the devices are connected via Eurosens Defender MAX intelligent spark protection barrier.

Key elements of the monitoring system

1. Fuel volume monitoring.

Eurosens Dominator fuel level sensors provide highly accurate measurement of fuel volume in the compartments of the tanker. These devices allow real-time monitoring of liquid level changes, preventing possible theft and discrepancies during transportation.

2. Compartment access monitoring

Eurosens Degree tilt sensors (or Eurosens Degree BT wireless sensors) are installed to control access to hatches and drain valves. They detect any unauthorized opening of the compartments by transmitting data to the monitoring system on the position of the compartment lid. The same sensor is installed on the lid of the fuel distribution box and controls access to the gas tanker’s drain valves.

3. Monitoring the openings of the bottom valves

Eurosens DPS pressure sensors record the opening times of the bottom valves to analyze fuel draining processes. The information on valve opening times helps to prevent unauthorized drains and to confirm that maintenance operations have been performed.

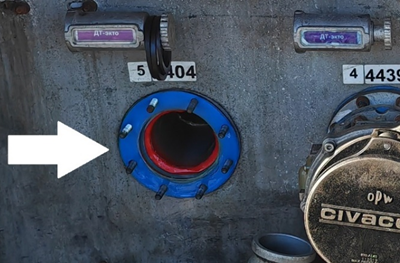

4. Monitoring the completeness of the fuel drain.

Eurosens LPS liquid sensors monitor the presence of fuel in the drain lines. They allow you to determine whether fuel has been completely drained from each compartment of the tanker, eliminating the risk of partial or unauthorized draining.

All system elements are interconnected via an industrial RS485 network, ensuring reliable data transfer and integration with telemetry systems. To ensure explosion protection, the equipment is connected via the Eurosens Defender MAX intelligent intrinsic protection barrier. In addition to creating intrinsically safe circuits, this barrier also interrogates sensors in the hazardous area and monitors the current consumption of devices for remote diagnostics.

All sensors are installed one for each compartment, additionally a tilt sensor is installed on the lid of the fuel distribution box. Total – for a semi-trailer with 5 compartments the total number of sensors reaches 21 pcs. As mentioned above, all sensors are interrogated by the Eurosens Defender MAX spark protection barrier. If the GPS tracker does not support transmission of such a large number of parameters, it is possible to read from the barrier only the necessary information or generalized parameters (for example, “all compartments are drained”, “all compartments are closed”).

The system can be supplemented by other control and automation devices (grounding control sensor, connection of fuel dispensing flow meter) at the customer’s request.